Lean Rapid Improvement EventsEngaging people to take action on waste and reveal more opportunities

-

Intro Video

Lean Rapid Improvement Events

-

Rapid Improvement Events

“A Lean / kaizen event is an active ‘hands on’ team based event, focused on the application of Lean principles and tools to solve problems and take action on identified waste”

Our Lean events are tailored towards engaging and involving both leaders and front-line personnel to help solve identified problems using lean tools, developing teamwork, and making improvements during the event to create new processes. These events are intensive and yield major benefits because of their focused approach.

Kaizen just means ‘Small changes for the better’ or simply ‘Continuous Improvement’ using the spirit for improvement mindset that we teach and practice. This kaizen attitude helps change not only the processes and system of work, but the culture with a strong team building component. Download PDF Flyer below

-

Testimonials

MFB

“...Andrew’s facilitation, challenge and guidance helped us to create a more efficient process that ticked all the boxes to deliver Customer value but more than that provided awareness of the principles and tools to repeat it...”C.I Manager, TAFE

2016-06-28T06:15:06+00:00“...Andrew’s facilitation, challenge and guidance helped us to create a more efficient process that ticked all the boxes to deliver Customer value but more than that provided awareness of the principles and tools to repeat it...”C.I Manager, TAFE

https://www.leanleadershipcoach.com/testimonials/corey-paton/Alan Wood

“Andrew’s passion, engaging style and captivating presentations, classroom video’s and fun stories not only kept us entertained but provided great learning and positive outcomes...I would recommend these courses to everyone...”Project Manager, BAESYSTEMS, UK

2016-06-28T06:16:07+00:00“Andrew’s passion, engaging style and captivating presentations, classroom video’s and fun stories not only kept us entertained but provided great learning and positive outcomes...I would recommend these courses to everyone...”Project Manager, BAESYSTEMS, UK

https://www.leanleadershipcoach.com/testimonials/alan-wood/Kelly Anne

“I came away with more than how to improve a business and processes, I was energised, felt motivated, empowered and ready for positive action with a new paradigm”Business Services Specialist, MFB

2016-06-28T06:17:20+00:00“I came away with more than how to improve a business and processes, I was energised, felt motivated, empowered and ready for positive action with a new paradigm”Business Services Specialist, MFB

https://www.leanleadershipcoach.com/testimonials/kelly-anne/HR

“Probably the most valuable 2 days we could have had as a Management team to get us all on the same page and understand that we as leaders need to commit and change ourselves”HR Manager, BAESYSTEMS

2016-06-28T06:18:18+00:00“Probably the most valuable 2 days we could have had as a Management team to get us all on the same page and understand that we as leaders need to commit and change ourselves”HR Manager, BAESYSTEMS

https://www.leanleadershipcoach.com/testimonials/corey-paton-2/Brigadier

“...Andrew’ challenged our reality and fixed paradigms, helped us to see waste, poor practices and behaviours, set stretch targets and helped us to understand how to do things better with the training, diagnostics and kaizen events...”Commercial Office, ADF

2016-06-28T06:19:21+00:00“...Andrew’ challenged our reality and fixed paradigms, helped us to see waste, poor practices and behaviours, set stretch targets and helped us to understand how to do things better with the training, diagnostics and kaizen events...”Commercial Office, ADF

https://www.leanleadershipcoach.com/testimonials/peter-murphy/RAAF

“Without buy in and direction, the journey is much harder so we were very glad to do this as a team and an experienced facilitator who understood our needs and had the right experience and knowledge.. ”C.I Manager, RAAF

2016-06-28T06:20:26+00:00“Without buy in and direction, the journey is much harder so we were very glad to do this as a team and an experienced facilitator who understood our needs and had the right experience and knowledge.. ”C.I Manager, RAAF

https://www.leanleadershipcoach.com/testimonials/pete-ley/Peter Ley

“…We thought we had good processes until we looked at them with Lean eyes and realised most of it was non value add or pure waste...unbelievable insights and gave us the impetus for change...”Ops Director, BAESYSTEMS

2016-06-28T06:21:16+00:00“…We thought we had good processes until we looked at them with Lean eyes and realised most of it was non value add or pure waste...unbelievable insights and gave us the impetus for change...”Ops Director, BAESYSTEMS

https://www.leanleadershipcoach.com/testimonials/corey-paton-3/BAESYSTEMS

“…In our Kaizen event, we set goals, knew what to target and we made changes there and then. It was such a great team effort and transformation ...brilliant result...”C.I Manager, BAESYSTEMS

2016-06-28T06:22:04+00:00“…In our Kaizen event, we set goals, knew what to target and we made changes there and then. It was such a great team effort and transformation ...brilliant result...”C.I Manager, BAESYSTEMS

https://www.leanleadershipcoach.com/testimonials/1055/Corey Paton

“…When taught like this, improvement is easy. The simulation game provided a lot of insights, thoughts and learning about a Lean approach and how this approach could work in our business...”Operations Director MFB

2016-06-28T06:22:49+00:00“…When taught like this, improvement is easy. The simulation game provided a lot of insights, thoughts and learning about a Lean approach and how this approach could work in our business...”Operations Director MFB

https://www.leanleadershipcoach.com/testimonials/corey-paton-4/RAA

“…Very enlightening as to why Lean can fail if it is often seen a s project, not a continuous journey. Very practical, engaging, fun and the mapping helped us see our business through new eyes ...”C.I Manager, RAA

2016-06-28T06:23:46+00:00“…Very enlightening as to why Lean can fail if it is often seen a s project, not a continuous journey. Very practical, engaging, fun and the mapping helped us see our business through new eyes ...”C.I Manager, RAA

https://www.leanleadershipcoach.com/testimonials/1057/BAESYSTEMS

“…The Laan Awareness training was great, good theory, hands on practical and great engagement with high energy which made the learning easy and fun....Andrew totally opened our eyes to new possibilities and thinking...”Operations Director, BAESYSTEMS

2016-06-28T06:24:31+00:00“…The Laan Awareness training was great, good theory, hands on practical and great engagement with high energy which made the learning easy and fun....Andrew totally opened our eyes to new possibilities and thinking...”Operations Director, BAESYSTEMS

https://www.leanleadershipcoach.com/testimonials/1058/Corey Paton

“…The Lean Leadership Academy brought together all the jigsaw pieces and especially how to act as a Leader to support and sustain improvement...”Ops Director MFB

2016-06-28T06:25:19+00:00“…The Lean Leadership Academy brought together all the jigsaw pieces and especially how to act as a Leader to support and sustain improvement...”Ops Director MFB

https://www.leanleadershipcoach.com/testimonials/corey-paton-5/Red Cross Blood

“I have been on root cause analysis courses before but this was so much better. It was more engaging, the practical examples were great and I learned so much more than I thought I would do. Thank you”C.I Co-Ordinator, Red Cross Blood

2016-06-28T06:25:55+00:00“I have been on root cause analysis courses before but this was so much better. It was more engaging, the practical examples were great and I learned so much more than I thought I would do. Thank you”C.I Co-Ordinator, Red Cross Blood

https://www.leanleadershipcoach.com/testimonials/1060/C.I Specialist

"...We identified an 80% reduction in our lead-time through a Lean diagnostic and then executed the plan which was just an unbelievable result…thanks Andy”Ops Manager - MFB

2016-06-28T06:26:44+00:00"...We identified an 80% reduction in our lead-time through a Lean diagnostic and then executed the plan which was just an unbelievable result…thanks Andy”Ops Manager - MFB

https://www.leanleadershipcoach.com/testimonials/1061/C.I Specialist – MFB

“…I knew of all the lean tools before but had never used them in a practical way before so it was really helpful, it all made sense and the benefit was amazing, especially how people now recognised how these improvements made things easier..."Change Agent MFB

2016-06-28T06:27:22+00:00“…I knew of all the lean tools before but had never used them in a practical way before so it was really helpful, it all made sense and the benefit was amazing, especially how people now recognised how these improvements made things easier..."Change Agent MFB

https://www.leanleadershipcoach.com/testimonials/1062/Senior Leader – BAESYSTEMS

“…Andrew gave us some new insights as he took us on a Gemba walk with the team through one of our Business Processes. We gained some excellent new knowledge about the process and as we asked questions started to see and understand the causes of delays, bottlenecks and people's frustrations ...awesome..."General Manager

2017-03-22T10:26:13+00:00“…Andrew gave us some new insights as he took us on a Gemba walk with the team through one of our Business Processes. We gained some excellent new knowledge about the process and as we asked questions started to see and understand the causes of delays, bottlenecks and people's frustrations ...awesome..."General Manager

https://www.leanleadershipcoach.com/testimonials/senior-leadership-team/

Key Modules

+ The Lean / kaizen event is an accelerated approach to improvement and where the action happens. It is high energy implementation with a multi disciplined team to engage and focus people on a particular area, process or part of the business in applying the tools and thinking of continuous improvement to address issues causing waste and frustration.

+ The outcome of these events varies depending on the problems and goals set, but always deliver change in alignment and agreement with team members and Leaders using the ‘Kaizen Spirit and attitude’. Events are generally focused on the small, quick wins / improvements that make a big difference in Performance, and this happens over the course of a week OR can be spread out as a number of focused days, depending on what suits best.

+ More importantly an event approach can help build momentum and the appetite for further change and also develops a longer term plan of improvements and actions to ‘sustain the gains’ going forward as part of a strategic plan.

+ Other Projects, events and workshops can also be formed off the back of a Lean Event as we collectively identify the next level of issues and opportunities.

Getting Lean for Business & Body…

Getting lean for business is like getting lean in body shape. It is about aiming for a vision of where you want to be in physical shape as a vision and goal, understanding where you are now and overcoming the challenges and obstacles to get there. It may require a new training regime, work out methods, a better diet to lose body fat as well as exercises to increase muscle growth…but like meeting any goal, it requires commitment, discipline, determination and perseverance to achieve it and sustain it…

Contact Us

Formula 1 apply the Principles of Lean as a SYSTEM

An F1 Pit-stop Team are Customer focused, share a common goal, and create a value adding, standardised and optimised process. People are engaged, highly motivated and feel part of a bigger purpose that challenges the status quo. They are always looking for the next improvement or edge to outperform the competition, and improve results, with a scientific approach, for personal pride, the team and the customer. We bring the same kaizen focus to your business using Lean sigma thinking, principles and tools to build a SYSTEM for improvement…How is your BUSINESS SYSTEM performing?

Contact Us

Inner game of Business is like Sport

Tennis is like Business, it is a game of the mind, it is strategic, it is physical, it requires great skills and knowing the right technique is critical to avoid trying harder than is required. The right technique can leverage power and save energy, the same as in business, finding efficiencies makes the job easier and quicker. Like business, tennis requires a lot of practice, dedication and commitment to be the best and is an ongoing pursuit to create an advantage to win. It is often 80% belief and 20% skill that makes the difference and we show you how to do it the easy way...

Contact Us

Business is like a Sport – We play to win!

High Performance cyclists perform as a team. They have goals, a strategy, a plan and they measure and track their performance to meet those goals. They define what they want to achieve, they measure every part of their process, especially the performance output of the cyclist, and analyse this data as a scientific experiment to optimise the inputs to improve the output for the most efficient and effective bike set up combination with the power, strength and endurance of the cyclist. This is how we aim to look at your business to make work easier , simpler and better…

Need Coaching

High Performance

Like a high Performance athlete, sometimes it is more than just talent or technique that is required to be successful. It is the ability to overcome problems, deal with obstacles and remain positive and focused on the goal in the face of adversity and struggle. Having the perseverance, dedication and commitment to keep going when times are tough and the staying power to pick yourself up is what truly separates the good from the great. This is all about what is in the mind and we help with both mind, technique as well as approach for improving your performance…how are you Performing? .

Lean Coaching

Quality Processes

A great process is one that is ‘Precise’ and ‘accurate’ or centred and within a small spread. This represents small variation and minimal errors. In six sigma terms this would be a repeatable, consistent, standardised and optimised process. This is a key goal and is measured by the output but controlled by the inputs from the variables. Problem solving the input causes is essential to process excellence and we help you to achieve this to reduce waste, time and money…how are your processes?

Contact Us

Are you trained in the Martial Arts of Business?

Karate is a self defence practice based on martial arts. It requires years of training, practice and mastery to become a black belt. It is not a training course but the process of learning self discipline, commitment, and dedication towards a goal. It makes the body strong, in flow, and is a spiritual journey of self discovery and improvement. Getting Lean is also a way of life. It is a practice and lifestyle, not a trend or fad and like Karate, improving business performance requires a coach or sensei to nurture skills, guide and ensure you are ready for next level of advanced training…are you ready or need help?

Contact Us for Coaching

True Leadership

Leaders lead others, they take charge, show belief and commitment towards a purpose and inspire trust that people want to follow. True Leadership is creating a shared vision, and aligning / engaging people to follow in the pursuit of this purpose and bringing out the best in people to achieve it. Leadership is a skill that can be learned and we help develop leaders in the pursuit of Continuous improvement and innovation to be the best they can be and to set the example for others...

Enquire about Lean Leadership Academy

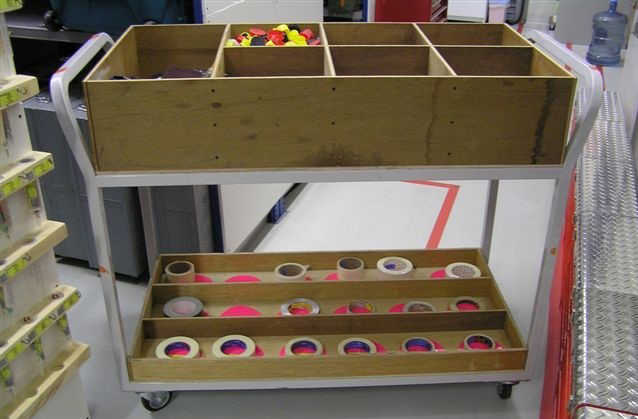

5S Workplace Organisation & Flow

5S Workplace Organisation is about creating a workplace where all information, equipment, files, tools and knowledge can be reached within seconds to support your daily tasks and work. In the achievement of this goal it is necessary to create a clean, clear, organised, visual, transparent and standardised environment. We have implemented 5S & Visual Management in many companies to improve Safety, Quality, Efficiency and a more professional image. How is your workplace set up for success?

Contact US

How ‘Fit & Healthy’ is your Business & Leaders?

Are you getting the results you want? Do you have the right mind-set & Leadership skills for effective change? Do you have an inspiring Vision, Strategy, Goals, Plans? How aligned & engaged are your people? Are your Customers happy? Are your processes optimised to deliver value? And are you going backwards with improvements? If so, maybe you need some help…call for a FREE Consultation

Contact Us

Visual Management

The power of Visual Management is the ability to ‘See at a glance’ the status, problems and deviations from standard to be able to respond quickly and adjust accordingly. Whether this is a visual metric, a visual standard or information, creating this visibility and transparency is the goal to monitor and control the key parts of your business to help everyone see it and empower others to identify and fix. The quicker problems are seen, the quicker a countermeasure can be found to reduce waste and make improvements. How is your Visual Management?

Need Training / Coaching

Standardised Quality Processes

Creating standardised, optimised, systemised processes that deliver consistent, repeatable quality each time, every time, on target is one of the goals of Lean. Being able to identify and eliminate errors, defects and eliminate mistakes means the output is improved for no extra effort…What processes are causing your business a headache?

Need Training / Coaching

How do you measure your Performance?

High Performance is knowing the score and status v the goal or target. Getting immediate feedback on performance helps to make adjustments real time and make improvements. Creating Visual management of performance helps to see at a glance the status against the standard and to see problems quickly and provides clarity on where to focus. Lean Sigma helps to design this into the daily process of reviewing performance and being able to quickly prioritise issues and solve them as a team…what do you do?

Speak to a Lean Coach

Team Work

Basketball is a team sport, like business. Working together to win the game. Using the right strategy combined with skill, agility, tactics and a game plan. Reviewing this frequently and changing the play as required to get the results. People are empowered to use their skills and guided, encouraged and supported by the leader / coach, which is similar to the inverted triangle concept in business…how are you teams working together?

Get in Touch

The Power of Visioning

Without a Vision, Strategy or Plan, any direction will do. Without a destination or goal, how can we expect others to consciously direct themselves towards achieving it…Fail to plan, plan to fail…we specialise in developing and deploying a compelling vision, helping to communicate it to the business, and align everyone to the vision and goals so everyone knows how they contribute…do you have a shared, compelling vision and goals?.

Contact Us about Blue Sky Visioning

Lessons from Sport

Like Business, Golf requires a long term and a short term game. A long term vision and strategy but tactical short term steps to get there. Use different clubs for different situations like improving a process may require many different tools to identify problems. It’s not a one size fits all. A great golfer has a caddie and coach to help him/her create the edge on local courses and it’s the 1% change that can make the difference in results in Sport and Business…how is your edge for competitive advantage?

Contact a Coach

© 2026 Lean Leadership Coach All Rights Reserved.